Sayfa yükleniyor...

IN STOCK

1 / 6

Tıkla: Tam ekran • Kaydır: Geçiş

Product Details

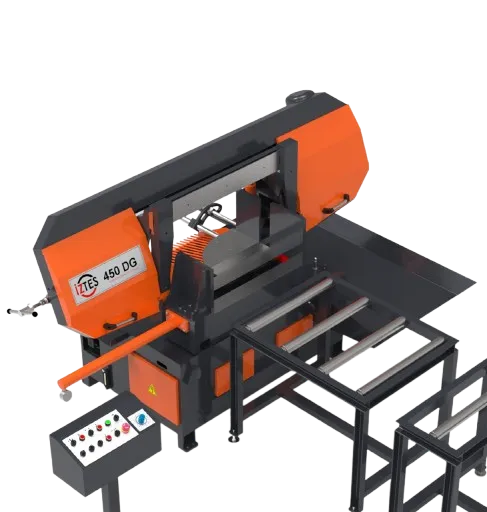

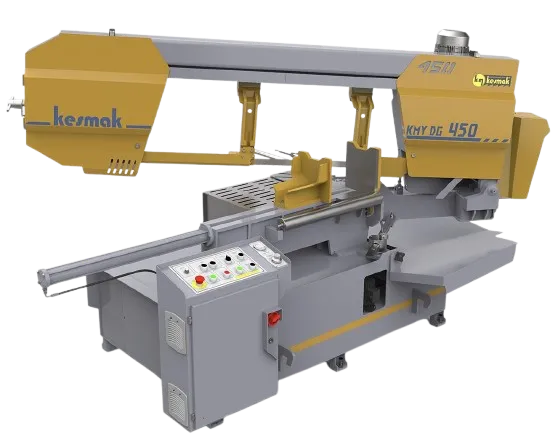

Kesmak KMY DG 450 Angled Semi-Automatic Band Saw

The Kesmak KMY DG 450 is a powerful angled semi-automatic band saw designed for professionals in the metalworking industry seeking high precision and efficiency. It stands out with its robust construction and user-friendly features.

Advantages

- Offers high-precision angled cutting capabilities.

- Semi-automatic operation reduces operator fatigue and increases productivity.

- Durable construction ensures long-lasting use.

- Wide cutting capacity accommodates various material sizes.

- Easily adjustable cutting angles provide flexible production options.

Areas of Use

- Metal workshops and factories

- Steel construction manufacturing

- Machine manufacturing industry

- Profile and pipe cutting operations

- Iron and steel industry

Technical Specifications

- Model: KMY DG 450

- Cutting Capacity: Various cross-sections at different angles

- Motor Power: High-performance industrial motor

- Band Saw Blade Size: Conforms to standards

- Angle Adjustment: Precise and easily adjustable

- Control System: Semi-automatic

Frequently Asked Questions

- Question 1: What materials can the Kesmak KMY DG 450 cut?

Answer: This machine is typically designed to cut various metal alloys such as steel, aluminum, and stainless steel. - Question 2: What does the semi-automatic feature mean?

Answer: In semi-automatic mode, the cutting process starts and ends automatically, while operations such as material feeding and angle adjustment are performed manually. This provides the operator with more control and flexibility. - Question 3: How should the machine be maintained?

Answer: Regular inspection and replacement of the band saw blade, maintenance of lubrication points, and general cleaning are important for the machine's long-term and efficient operation. Instructions in the user manual should be followed.

Custom Production

Couldn't find the size you are looking for? Call us now for custom production.

Call UsProduct Catalog

PDFCheck the catalog for technical drawings and detailed usage data.